Sour Gas Testing

In the O&G industry, chemical environments can be brutal. Argen has the facilities, expertise and experience to get the job done right.

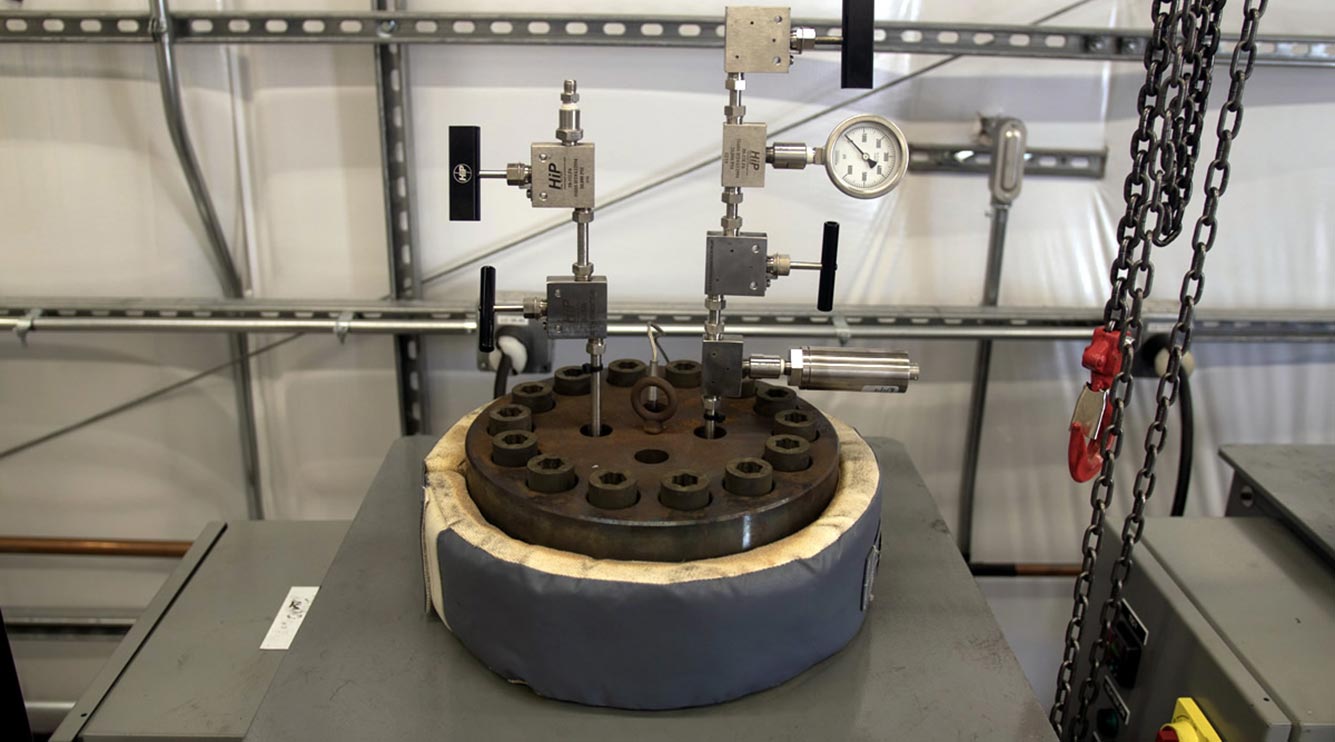

Selection and qualification of materials in the O&G industry requires subjecting the materials to simulated operating conditions. In many cases the environment comprises sour gas (hydrogen sulfide, H2S), typically in combination with other gases. Argen carries out sour gas aging of materials according to both standardized and custom protocols. We follow the aging with mechanical and analytical testing to provide our clients with results to make decisions, whether for standard test qualification or for gaining fundamental understanding of the system.

Capabilities

- Exposures in H2S / CO2 / CH4 and multiphase mixtures

- Pressures to 15,000 psig

- Temperatures to 320 °C

- Temperature and pressure cycling on seals

- Full datalogging

- Multiple large vessels capable of aging several materials simultaneously

- Dozens of smaller vessels for segregated aging

Example Test Standards

- ISO 23936

- API 6A conditions EE/FF and GG/HH

- NORSOK M-710

- API TR 6J1

- API 17D

- Customized sour RGD